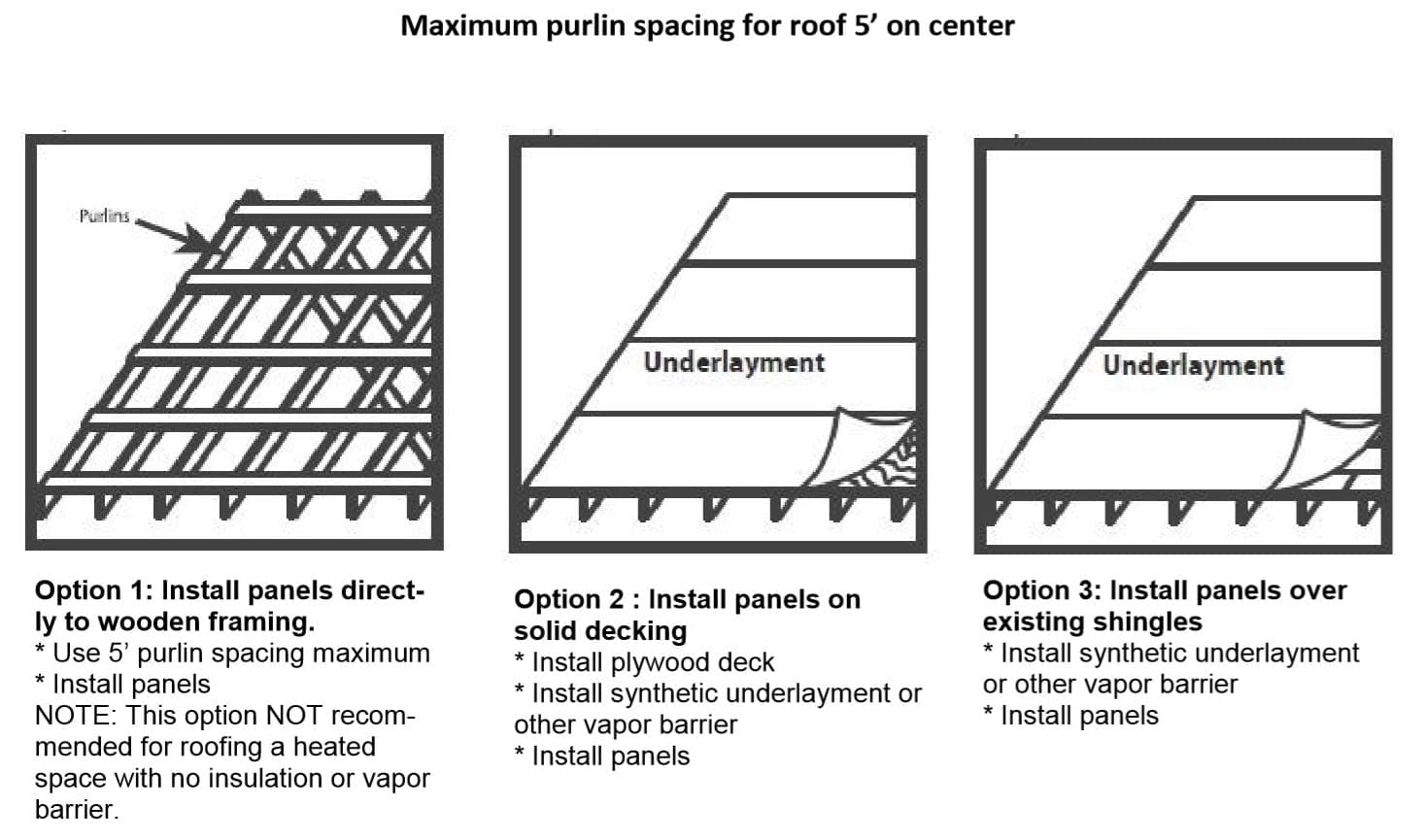

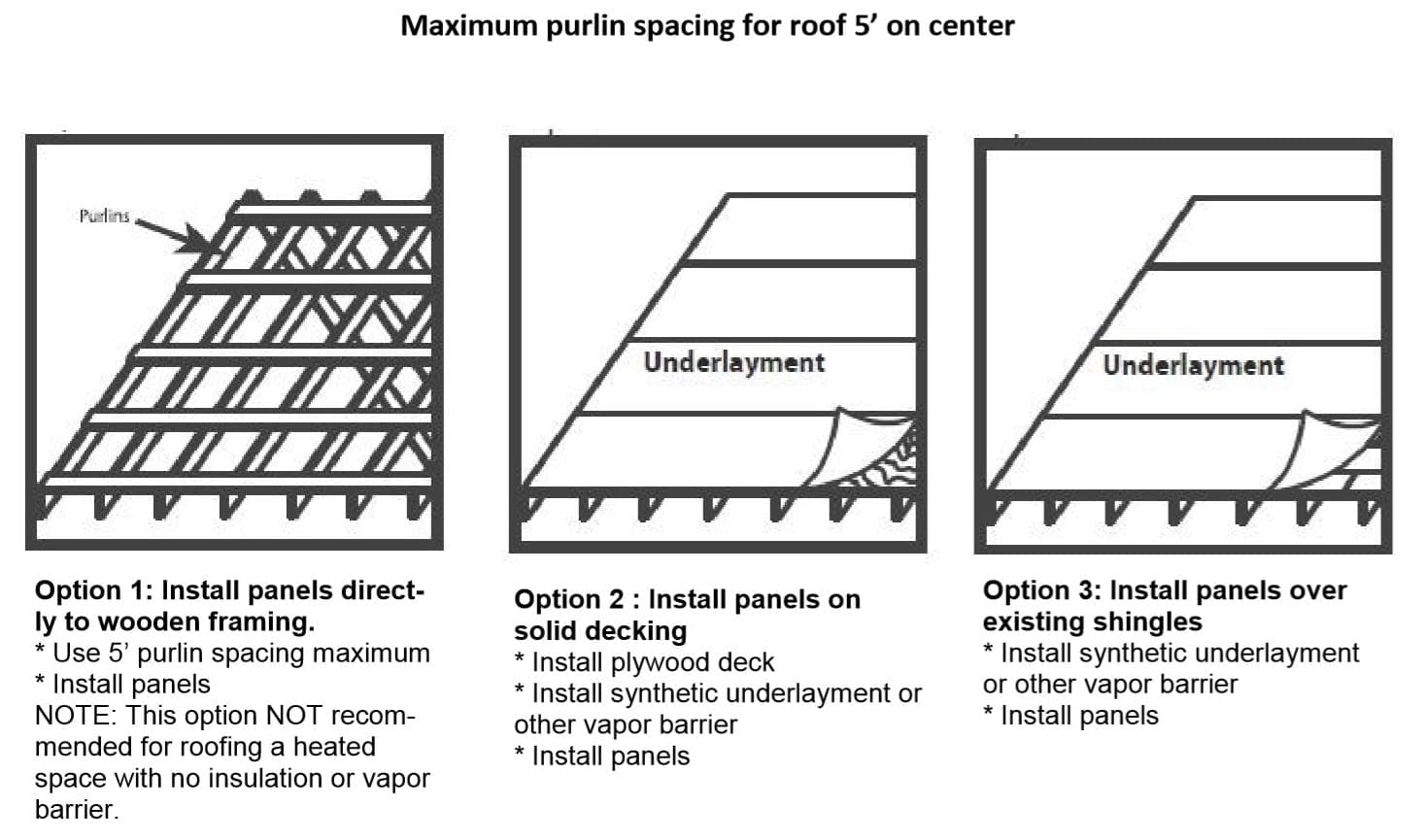

Installing translucent plastic corrugated roof panels.

Purlin spacing for pvc corrugated roofing.

Polycarbonate roofing installation guide ph.

Z purlins are connected to the rafters using cleats.

C3 fix side laps and miss 2 hit 1 miss 3 hit 1 miss 2 etc with approved fasteners alone.

While panels may not fail under heavy snow loads strain at fastening points can cause slight cracking.

Panel basics corrugated metal panels often called tin because in the past such panels were sometimes made of tin are typically steel or aluminum sheets that are used as a roofing material.

Corrugations should run in a straight line between the highest and lowest points and at a right angle to the purlins the intermediate supports.

The typical spacing standards for residential and commercial buildings are about 1 to 2 foot.

Corrugated sheet roofing material is widely available and easy to use.

End purlins and periphery of roof to be fixed every 2nd crest.

In heavy snow areas 500 series or greater panels are recommended and closer spacing of purlins should be considered.

08 9459 7402 email.

Note compliance with e2 as1 is dependent on purlin spacing and gauge of roofing.

Doubling up in the valleys refer to the installation manual for the proper on center spacing and be sure that the purlin is attached to the roofing truss.

When framing the roof the spacing for roof trusses should not exceed 24 inches 61 cm and purlins should not exceed 36 inches 91 cm apart.

With approved fasteners alone.

In some cases however the exact spacing of the rafters doesn t matter if the roof has other means of supporting the metal panels.

For heavier material such as gage steel the metal roof purlins spacing length could go up to 4 feet.

All purlin joints must be supported by a rafter.

For the lighter material such as lightweight aluminum the common spacing length is 4 inches of clear gap.

Minimum recommended purlin size is 4 x 2 50mm x 100mm in timber or z140mm x 1 6mm in steel.

In the valleys due to the angle typically produced at the valley and the use of transition flashing it is essential that the purlins are doubled in the valleys that is two purlins.

Step 3 purlin spacing suntuf is supported on the structure via purlins these are the bearers that run left to right along the width of the roof the maximum purlin spacing for the corrugated profile is 800mm centres on the first and last purlins and 1 meter centres for the intermediate purlins.

Minimum purlin size will vary according to span.

End purlins and periphery of roof to be fixed every 2nd crest.